Company Profile

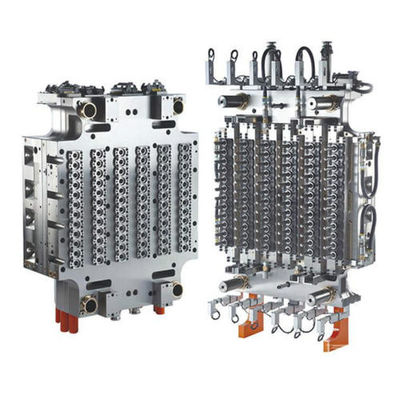

With over 15 years in Taizhou, we are a professional manufacturer of plastic molds, injection molding machines, and complete auxiliary equipment—focused on solving your core challenges in plastic production.

Struggling with delayed mold development, inconsistent product quality, or fragmented supply chains? We create one-stop plastic injection molding solutions covering conceptual design, rapid prototyping, precision mold manufacturing, post-molding finishing, and technical support to streamline your workflow.

Our expertise caters to diverse industries (bucket production, warehouse & storage systems, baby products, furniture, home appliances, automotive components) to address industry-specific pain points, from custom mold demands to efficient production line setup.

Collaborating closely with clients across Europe, the Americas, Africa, and beyond, we deliver high-quality, durable molds and reliable equipment to eliminate production downtime and cost overruns.

Backed by rich industry experience, we prioritize precision engineering, on-time delivery, and responsive customer service—solving your supply chain worries and ensuring seamless project execution.

We invest continuously in advanced technologies and talent to stay innovative, ensuring our solutions meet international quality standards and adapt to your evolving needs.

Whether you need to reduce development cycles, improve product consistency, or secure a trusted end-to-end partner, we’re here to turn challenges into growth opportunities. Contact us today to discuss your requirements!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!